State of the art manufacturing

The best design idea is of no use if the execution is not professional. For this reason, we attach great importance to the training of our employees and to a machine park that is constantly at the cutting edge of technology.

Our production planners work hand in hand with our design engineers. Even during the concept and development phase, there is a close exchange on feasibility and the possibility of optimizing the design in terms of production technology. By keeping production processes simple, we ensure the necessary process stability. This is the basis for meeting our high quality standards, as well as the basis for our expectation of efficiency and thus cost optimization in our production.

We are convinced that the greatest value of a company lies in its employees. For this reason, we continuously invest in the further development of our employees. Over the years, our production employees have thus developed into specialists in their field, which enables us as a company to fully exploit the possibilities of our modern machinery.

Machinery

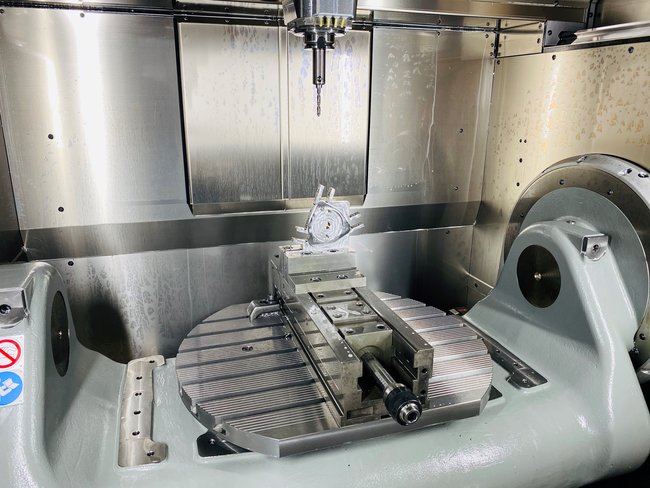

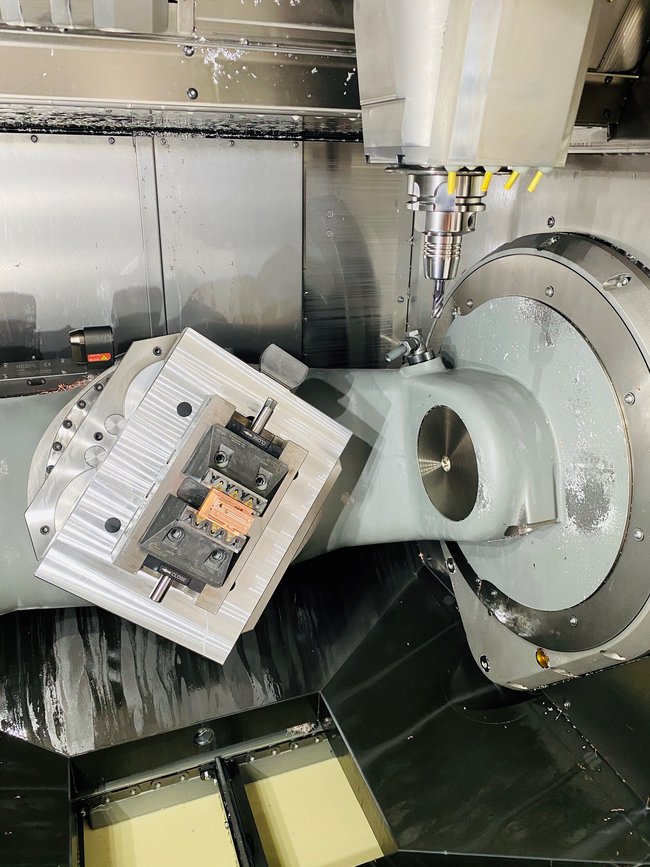

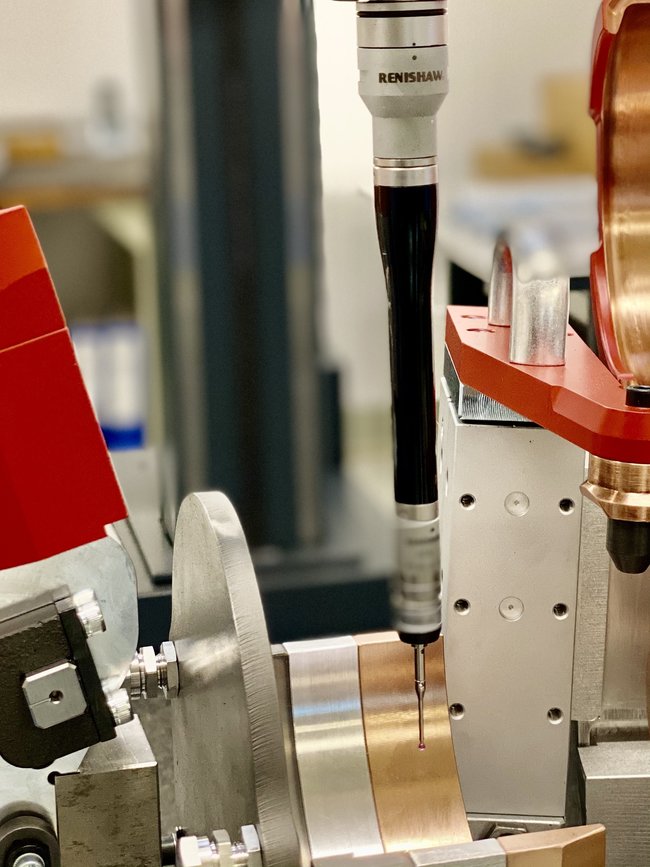

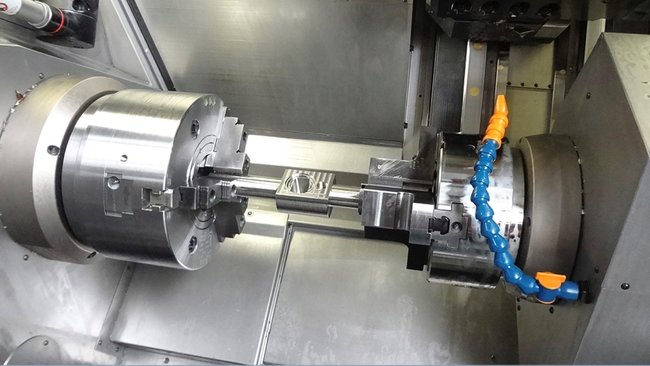

Precise and efficient production requires state-of-the-art and comprehensive machinery.

Our machinery is regularly modernized. This way we always stay on top of the technical development and are able to meet the increasing quality requirements. DKT has the most modern 5-axis CNC milling machines, a 7-axis turning-milling center, a CNC water jet cutting system and other machines for metalworking.

Your Contact

-

![]()

Markus Johänntgen

-

![]()

Michael Hoffmann

Deutsch

Deutsch